Mick n Janes 17.56OB writeoff rebuild

- Thread starter 1756mick

- Start date

Install the app

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It looks and sounds frighteningly pathetically inadequate ..... but unless they get belted with something big and hard, Ive not heard of one coming apart. So Jayco seemed to have got the formula right.I suppose it is adequate, for what it is to do

but

if they over engineered it with more strength, we would all be whining about the weight of our Vans,..........

Jayco wouldn't fit my outdoor shower where I wanted it, so I deleted it and asked for a wall plan showing internal bracing etc so I can do it myself. Here was me cursing them for the plan which had no bracing indicated .... now discovering they in fact had all the bracing indicted .... there just aint any.

Good to know (i think) I can bore holes in it with wanton random abandon.

Last edited:

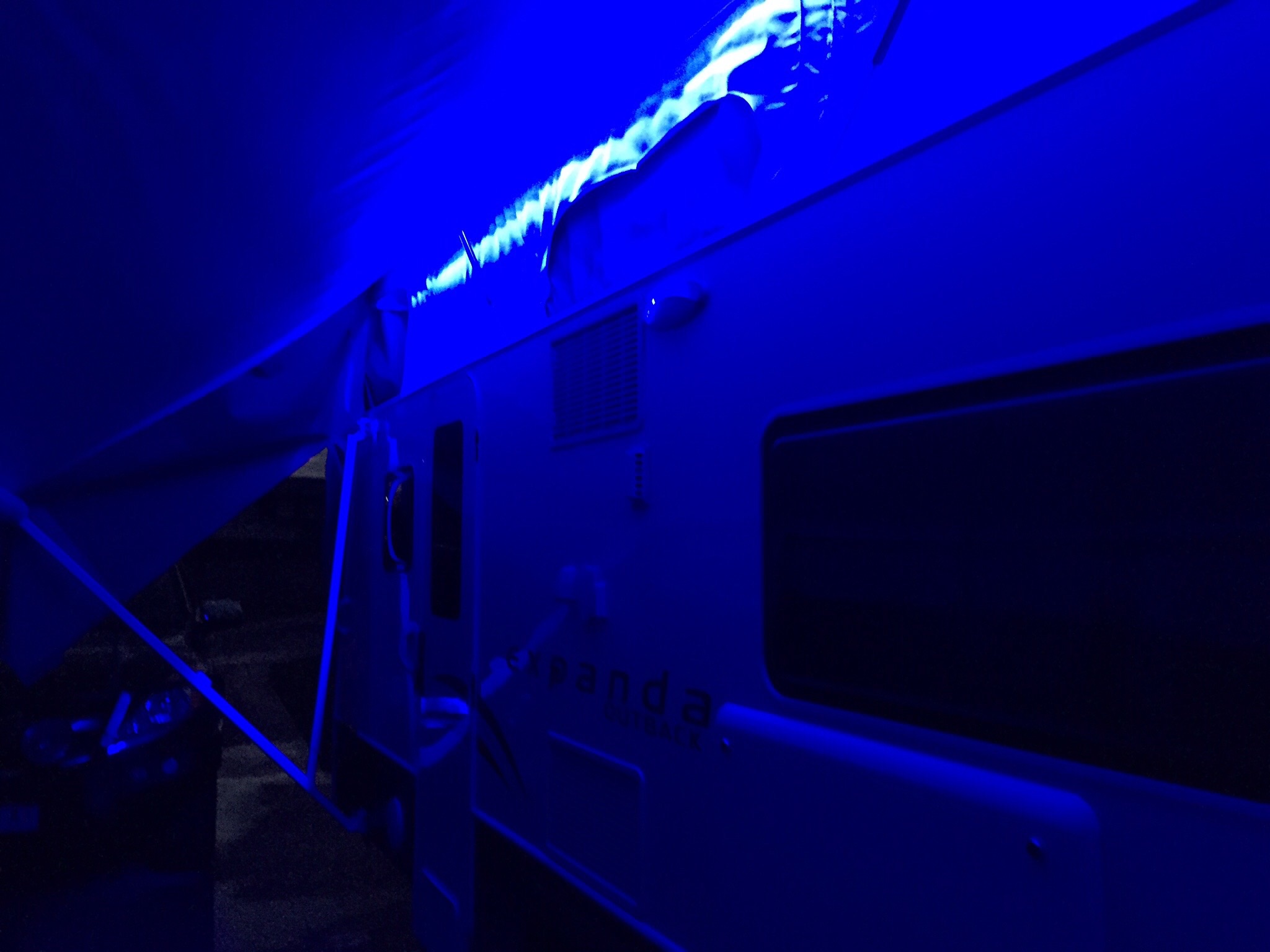

Added an LED blue stip light to the inside of the roof extrusion. Joined the power supply to the awning LED feed.. Suprisingly it is a lot of light and matches the blue factory LED's perfect

I think I would prefer the LED strip at the van end as opposed to the roller endAdded an LED blue stip light to the inside of the roof extrusion. Joined the power supply to the awning LED feed.. Suprisingly it is a lot of light and matches the blue factory LED's perfectView attachment 31195View attachment 31196

Got the idea for the table off the forums here. Thanks for sharing. Mitre 10 selling 1800mm tables for $39

I am with you Crusty and if your not planing on rolling out the awning at least you can still use the light on a full height van. But most of all you don't have to worry about damaging the awning if left on by mistake either.I think I would prefer the LED strip at the van end as opposed to the roller end

It sort of is finished. Just needs new decals and that's it.

I did make a few draw bar mods. Deleted the wheel carrier and moved the jockey wheel to outside, and upgraded the drawbar to 150x50 instead of 120x51. Installed the 12 pin plug and moved the original Anderson plug to the 12pin to match my BT50. Also fitted quick release gas bottle holders.

I did make a few draw bar mods. Deleted the wheel carrier and moved the jockey wheel to outside, and upgraded the drawbar to 150x50 instead of 120x51. Installed the 12 pin plug and moved the original Anderson plug to the 12pin to match my BT50. Also fitted quick release gas bottle holders.

Mate what a amazing job you've done there, hats off to you. Now it's time to get out and enjoy it.

And we are finally back after our initiation trip. Everything went perfectly. No hidden problems. I did notice that the lower aluminium roof extrusion develops some serious condensation on a cold night. Needs wiping down in the morning.

Not really, I made that thing toasty in there. Not used to the western QLD nearly winter nights. Gets a bit chilly.Did you leave some of the zips open in the poptop and windows open a little Mick? that helps a bit with the condensation a bit. Great to see you out enjoying all your hard work too mate!:encouragement:

Might try that next time though

The toastier you make it inside, the colder it is outside and the more people breathing out nice vapour filled air .... the more condensation unfortunately.

Half of the alum roof frame is exposed to the outside cold air which keeps the whole frame cold, and kind of acts like a fridge element condensing the moisture from the warm air. Regardless of outside weather, we always left the awning side poptop skirt window open which minimized condensation.

It was worse with the wind up campers and older expandas without the hardlids if you didnt use flies. The inside of the bed end roof would form condensation on it, and the first person to wake up and bump the van by jumping out of bed, would cause it to virtually rain in bed.

Half of the alum roof frame is exposed to the outside cold air which keeps the whole frame cold, and kind of acts like a fridge element condensing the moisture from the warm air. Regardless of outside weather, we always left the awning side poptop skirt window open which minimized condensation.

It was worse with the wind up campers and older expandas without the hardlids if you didnt use flies. The inside of the bed end roof would form condensation on it, and the first person to wake up and bump the van by jumping out of bed, would cause it to virtually rain in bed.

Even with the awning side pop skirt open like @Crusty181 .. We carry a quick dry towel that we run around the frame each morning.

True the awning side was actually ok.

I just thought it a poor design considering the amount or paper lamented cabinets that actUally touch the pop top extrusion.

However it is a vast improvement over my eagle as the bed would feel damp every morning and touching the canvas was a no go zone during the night.

I just thought it a poor design considering the amount or paper lamented cabinets that actUally touch the pop top extrusion.

However it is a vast improvement over my eagle as the bed would feel damp every morning and touching the canvas was a no go zone during the night.

Hi burnsy not 100% about nsw. My last van was from Sydney and was repairable. That was 2010 though.

Here's one I found now that has a repairable status http://www.manheim.com.au/damaged-v...-2015-atm-1-408kg?referringPage=SearchResults.

But it does say Qld. So really QLD is blessed unlike the other states..

I replaced the walls right side completely. Left side only the front 25%.

Roof was not bent just looked it, for the walls weren't supporting the 200kg load. The nose cone fiberglass was snapped in 6 places. I glassed it back up, bogged it, primed and 2k paint.. Hard lids, canvas was fine, a few touch ups here and there. A few of the internal cabinet panels I replaced or repaired, they come apart easy as.

Replaced the roof alloy extrusion, as per photos on my lawn.. Ex jayco only. Door frame outer ex Camec. Right window still 2 months away but I can live without it for the moment. $400 window and no stock Camec.

Ok here's my parts list: ( from memory)

Awning

Awning arms

Fiberglass skin 2mm x 8 lineal metres

6 sheets 3 mm ply

5 sheets 2.7mm polyester white internal ply

5 sheets 19mm polystyrene sheets.. Hahaha they cost $15 all up.. How do they make money?

Door outer frame

Roof extrusion

Fiberglass mat, resin, bog, primer paint.

Heaps of white sika about 6 sausages, and one tube black.

Laminex sheet to replace bench tops.

3 sheets 12mm marine ply

19mm alloy SHS 8 lengths x 8'metres

25mm as above 1 length

Body extrusions outer sections and mid one length only.

0.9mm checker plate powder coated black. Replaced all lower pieces.

3 sheets crappy jayco 12mm paper laminated ply. This is the cabinet material. Paper laminated really?? True quality.... NOT!!!

Handful of screws pop rivets, glues for applying the sheets etc.

150x50x3mm duragal for draw bar

Front hatches

Spray on deadener for nose cone lower.

A handful of other small junky clips brackets etc.

2 gas struts

power inlet sockets.

New AGM battery

Gas bottle brackets and reg.

3 cartons of beer, 2 bottles of Jim beam, 2 arguments with the missus, sunburnt 10 times, 5 alloy shavings in my foot and a mild case of welding flash. Oh and accidently unplugging the deep freezer for a lead to run the grinder on and forgetting to plug it back in... That was not a good experience.

WOVi fee

Roadworthy

Registration

Insurance

Camping In 4 weeks

Hey mate awesome job on the rebuild. Just wanted to ask a question in regards to the side wall checker plate is it the solid stuff or just the cheap stuff that comes in rolls was going to add some to mine for protection that's all cheers adam

Jayco only ever installed 0.9mm propeller plate. I could only find 0.9mm checker in mill finish. I powder coated it black.Hey mate awesome job on the rebuild. Just wanted to ask a question in regards to the side wall checker plate is it the solid stuff or just the cheap stuff that comes in rolls was going to add some to mine for protection that's all cheers adam

I reckon itS more cosmetic. And thin to keep down weight. A 2.4m *Try posting a bit more so your post isn't boring*.2m sheet was $55.

PS: propeller plate is the style in the banner above